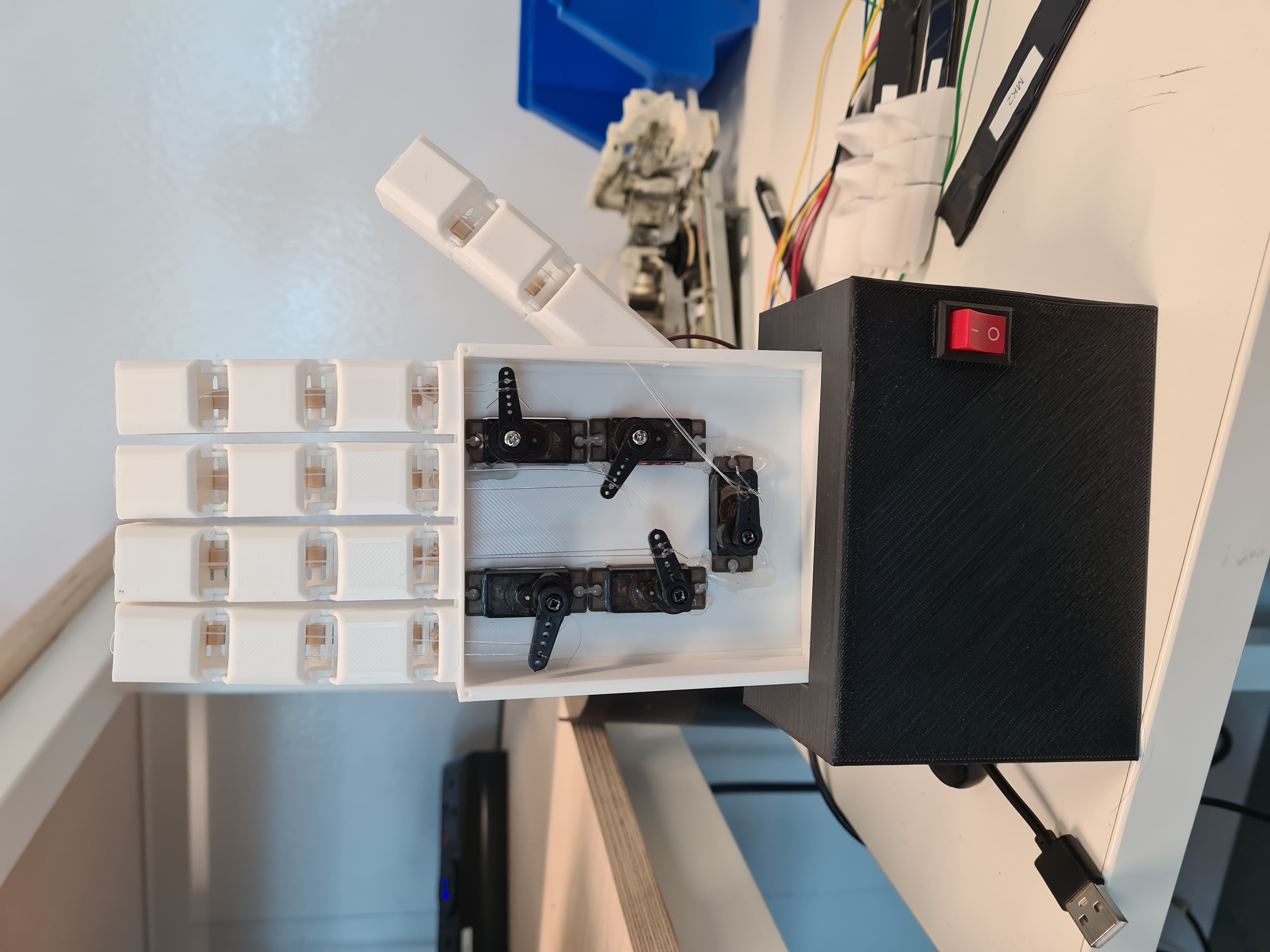

HI5 was one of my first-year university projects, developed independently over several months. The goal was to design an affordable, 3D-printable robotic hand capable of replicating human gestures. The prototype was modelled in Fusion 360, printed in PLA, and actuated using servo motors. Control was provided by an Arduino Uno, which received input from a custom-built flex sensor glove worn by the user. This setup enabled the robotic hand to mirror finger movements in real time.

After the initial submission, I continued development by replacing the glove with a Raspberry Pi and a PS EyeToy camera running Mediapipe hand-tracking. This upgrade delivered far greater accuracy and responsiveness, while removing the need for wearable sensors. The project proved an excellent learning experience, deepening my skills in 3D design, electronics, and programming.

HI5 was showcased at the university expo as one of the best first-year projects, earning positive feedback from both staff and students. It remains a rewarding milestone that sparked my long-term interest in robotics and mechatronics.

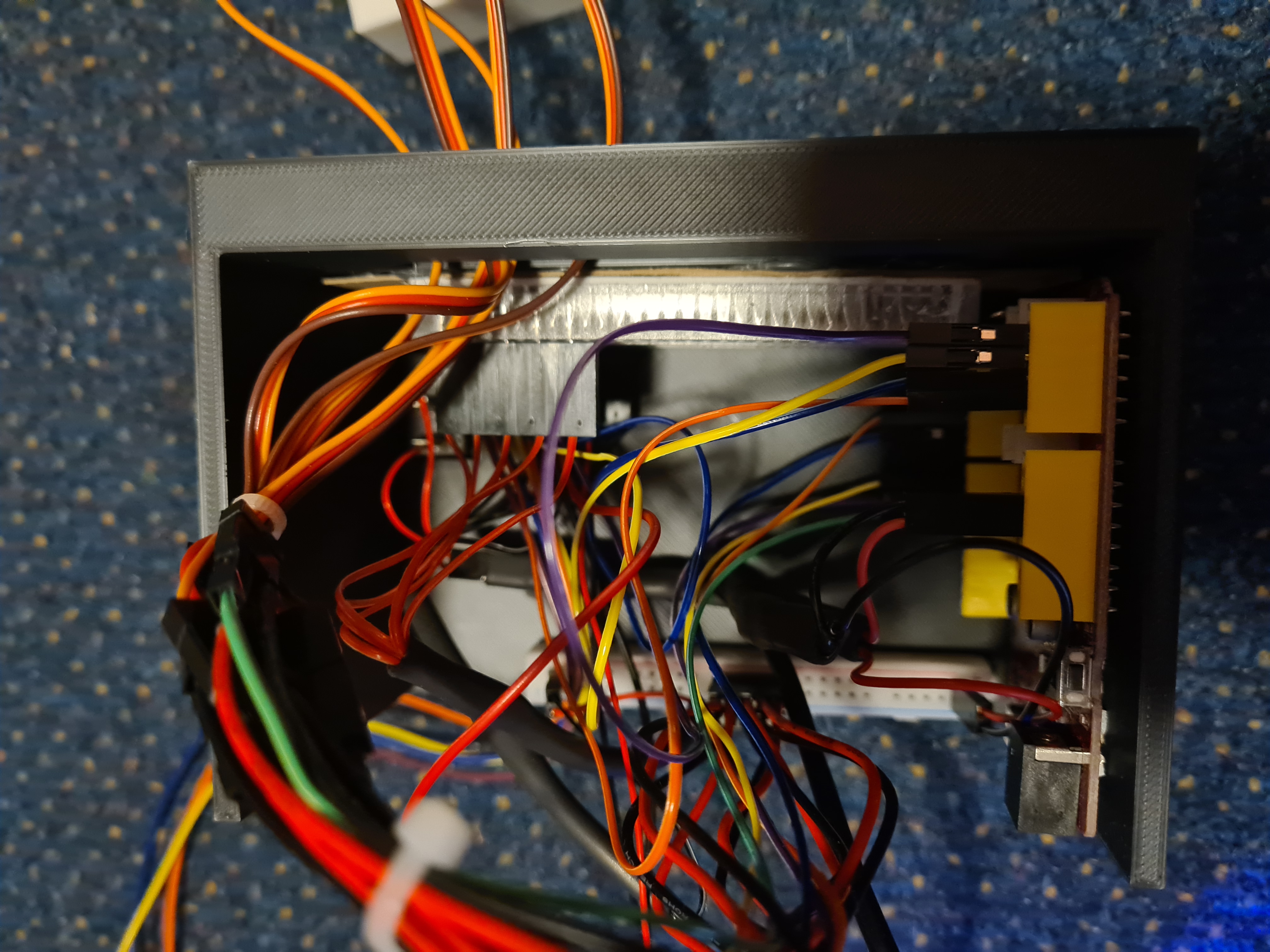

Since its creation, HI5 has continued to evolve through iterative improvements, including stronger finger designs, more print-efficient components, and the development of custom PCBs for enhanced control.